2 New patents issued to KAXITE recently

KAXITE has been studying with the polyamide extrusion and related injection parts for over 14 years, from now on she has 10 patents issued and 4 patents under application.

For achievements of polyamide extrusion, we can do what they can't do all over the world:

|

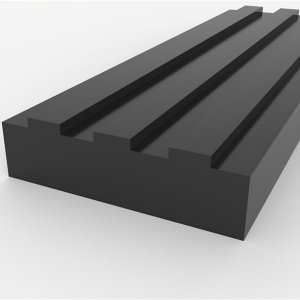

1. Super thick Fiberglass reinforced polyamide has higher mechanical performance strength, now applicated to replace some thin metal products, such as aluminium profile, now the most common thickness which easy to manufacture is 2mm. But now if clients need higher thickness, such as 10mm, 14mm... Actually the thickness is widely used for automatic production line, to replace the pressed and machined PP guiders. Here we can extrude such thicker parts out and "ensure the flat of surface". |

|

|

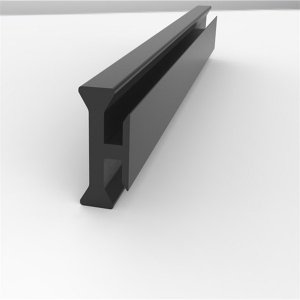

2. Tiny cavity It is such a special application, that we need the polyamide thermal breaks hard, high mechanical performance, but still should be "soft" enough for well assembling and protective for windows, and resistant from rough wind. So mostly when we need a bigger area section polyamide, cavities be added. But when the area is just not so big to add a cavity, nor so small to ensure soft, a tiny cavity will be needed. Most people bypassing the point but we met it, and solved it. |

|

|

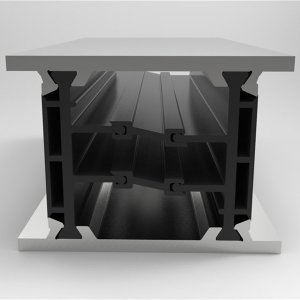

3. Longer legs We keep moving on and want to get better Uf values (the thermal conductivity of frame), so we even broke the air between aluminum, but polyamide is so hard to be extruded out due to its sticky and glass fiber, legs can only be "assembled" onto the mian parts, refer to picture above. But we solved the cooling system and made it out as a whole part! No need of assembing, and even be adjustable for different size of aluminium profiles. |

|

|

4. flame retardant but no mechanical performance lowered down Now more and more curtain wall systems and facade systems need the plastic thermal breaks be flame retardant. Their are so many kinds of additives for polyamide flame retardant, but all leading to the lowering off for mechanical performance, the nature of PA66 GF25. We are the only ones who granuled by ourselves, studied and researched, came out with solution for flame retardant PA66 GF25 profile but no mechanical performance lowered down! |

|