Method of distingushing genuine and false thermal barrier strips

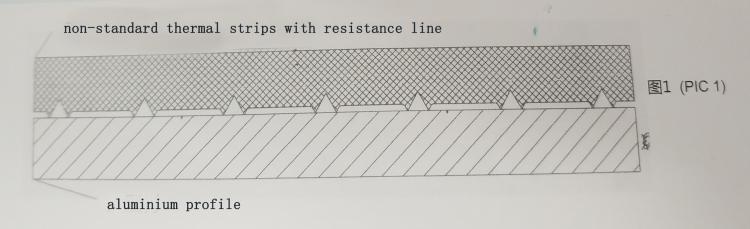

Thermal barrier strips must be pure nylon double 6,the shrinkage ratio is the same as the profile(PIC 1. All 4.2mm side resistance line are miscellaneous plastic products, must not be used on building profiles. Different shrinkage will loose, wire lines over time affect the shear force, resulting in door and window leakage. A bad influence, such as deformation.

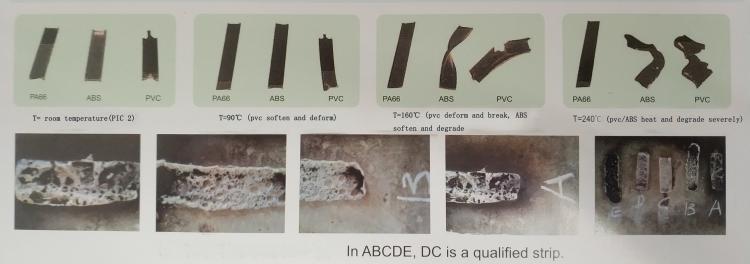

In view of the uneven nature of the domestic heat insulation market, the so-called “insulation strip ” has been manufactured by using PVC(styrene-malondiene terpolymer)(PP) or even general plastic such as PVC, which can only be used as non-structural materials, instead of engineering plastics PA66(PIC 2-PIC 5). A simple method for identifying genuine and false insulation strips is provided: the thermal insulation strips made of PVC/APS/PA6(nylon 6)were placed in the oven,respectively.When heated at about 90℃,the thermal insulation strips were softened and degraded into PVC materials at about 160℃. PP materials and ABS materials were softened and degraded to PA66 materials at 210℃.However, the heat insulation strips of PA66 material have no devious change in appearance when the temperature is below 240℃.In short, only when at 210℃-240℃ high temperature, the appearance of no significant change is genuine insulation strip.

Rapid high temperature calcinations:as the saying goes, real gold is not afraid of fire,because the quality of each product depends on its raw materials.If the heat insulation strip is kept basically after burning, such as the heat insulation strip produced by other raw materials,it can not withstand high temperature combustion,the time is not only short but also not shaped.